Introduction

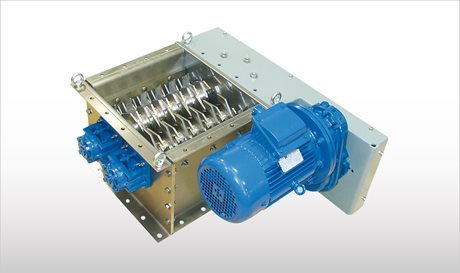

The DLP Lump Breaker is an efficient, economic machine specially designed for breaking up friable lumps in bulk materials discharged from silos, bins or hoppers.

Technical Specs

Description

The DLP Lump Breaker consists of a square cross section casing with upper and lower flange, two horizontal rotating shafts equipped with chopping knives, a grid to hold back lumps, four end bearing assemblies with integrated adjustable shaft seal, an appropriately sized drive unit complete with power transmission.

Function

The DLP Lump Breaker is the ideal device for breaking up material lumps which have formed during handling or processing but are soft enough to be broken up.

Quick rotation of special chopping knives through a fixed grid does the job. The presence of two rotor shafts results in high throughput rates.

Features

- Material: carbon steel, 304L stainless steel

- Two sizes available: 25 ~ 50 m3/h (15 ~ 30 cfm)

- Contains two rotor shafts equipped with chopping knives and a fixed grid to reduce clearance

- Drive unit with fixed speed gear motor or variable speed drive, chain or gear transmission

Benefits

- Sturdy and compact

- Modular design

- Compact shipping dimensions and easy to install

Download