Description

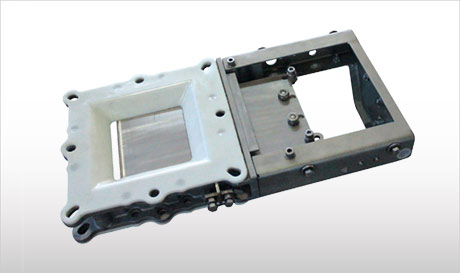

Low Profile VIB Slide Valves consist of two high pressure die-cast semi-bodies manufactured from aluminium alloy, a sliding blade in carbon or stainless steel, a carbon or stainless steel frame and a pre-stressed elastomeric seal manufactured from WAM’s unique SINT engineering polymer composite. The use of SINT engineering polymer composites considerably increases resistance to abrasion as compared to traditional valves. The valves are equipped with live-loaded seals which ensure extended durability and wear resistance, providing excellent sealing across the entire valve surface. Additional flange gaskets are not required. Low Profile VIB Slide Valves are available in a variety of configurations: the VIBQ version comes with a square inlet; the VIBC-type has a circular open cross section.

For the food industry a version with stainless steel blade and frame, as well as food-grade seal is available.

The VIB is a gravity Slide Valve for all kinds of powdery or granular materials stored in silos or bins.

Function

Low Profile VIB Slides Valves are used where flow of a dry powder or granular material caused by gravity or conveying has to be intercepted. Low Profile VIB Slide Valves may be fitted beneath hopper, bin or silo outlets, on inlet and outlet spouts of mechanical conveyors, as well as above the inlet of telescopic loading spouts.

The special geometry of Low Profile VIB Slide Valves and the various options in blade design enable their application in virtually all industries including food processing.

Due to their special design and to the engineering materials used, they represent a particularly economic yet most efficient solution in all product processing applications where contamination and material pollution are an issue.

Features

- PATENTED dust-proof, friction-free design

- Compact: small number of components, minimum overall height

- Compatible with WAM and CEMA flanges

- Safe sealing with no additional measures due to the all-round dustproof seal lips integrated into the polymer coating

- Highly abrasion-resistant, wear compensating, replaceable sealing system in SINT engineering polymer for standard or food-grade applications

- Integrated inlet deflecting material away from seals and rollers, thus reducing wear

- ATEX versions and food-grade version compliant with Regulation (EC) 1935/2004 available

- Interchangeable actuators: manual, pneumatic, electric gear motor

- Horizontal or vertical mounting

- Standard sizes: 150 ~ 400mm (6” ~ 16”)

Benefits

- No contamination due to carbon or stainless steel blade and valve frame lined with engineering polymer

- Dust, pellet and granule-proof thanks to special component geometry

- Highly abrasion-resistant due to replaceable SINT seal

- No downtime for seal adjustment

- Easy integration into the process thanks to light weight and eased handling

- Quick fitting thanks to WAM and CEMA flange compatibility

- High flexibility and time-saving maintenance due to interchangeable components

- Better performance as a result of friction-free contact design (no waste of actuator torque to increase friction)

- Safe operation thanks to total absence of pinch points and exposed moving parts

- Optimised maintenance thanks to small number of components

- Minimised residue and contamination thanks to low profile design

- Ex-stock delivery

Options

- ATEX versions and food-grade version compliant with Regulation (EC) 1935/2004

- Interchangeable blade in carbon or stainless steel

- Food-grade seals