Description

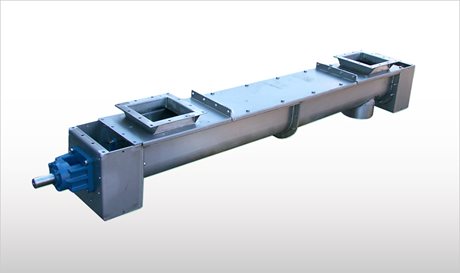

Extra heavy-duty MT / HT Trough Screw Conveyors and Feeders are designed for medium-high temperature (MT-series) and high temperature (HT-series) applications. For this reason intermediate bearings are absent. MT / HT are manufactured from carbon or stainless steel with appropriate surface treatment. They are made up of a U-shape trough equipped with at least one outlet spout, an end plate at each trough end, helicoid screw flighting welded on a centre pipe with flanged coupling at each end, two end bearing assemblies complete with offset shaft seal, and a bolted trough cover usually equipped with at least one inlet spout. Furthermore, MT / HT Screw Conveyors are equipped with a gear motor that suits the application.

Function

Designed for extra heavy-duty applications, MT / HT Screw Conveyors and Feeders satisfy the requirements of conveying or feeding regenerated sand in foundries, coal power stations, or drying plants.

Features

- Extra heavy-duty fabrication

- Wire welding

- XUC-type shaft seals with fibreglass seals

- Bolted trough covers

- Fibreglass gaskets

- Flanged shaft couplings

- Extra heavy-duty helicoid flights

- Insulation spacer (HT)High quality shaft seals with split packing glands (HT)

Benefits

- Application-specific design features

- Robust and durable

- Reliable in operation

Options

- Tapered inlet spouts

- Shoe inlets

- Square or rectangular inlets

- Trough flange brackets for hopper connection

- Semi-elastic couplings or chain power transmissions