Description

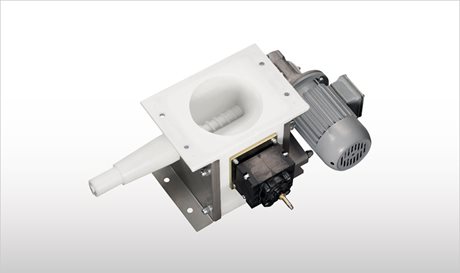

MBW Micro-Batch Feeders for continuous volumetric feeding of powdery or granular materials consist of a SINT engineering polymer FLEXFLO body with integrated feeder outlet pipe, a feeder screw and a drive unit.

Function

MBW series Micro-Batch Feeders for powder and granular material feeding are particularly suitable for free flowing and moderately flowing materials which do not tend to pack under pressure.

Fed via a bag opening hopper, a bulk bag discharger, or another feeding device, the SINT engineering polymer FLEXFLO body, with its particular geometry, ensures constant material flow and dosing through the feeder screw. To further facilitate material flow an additional pneumatic activator can be fitted on request.

Typically MBW Micro-Batch Feeders are used in plastics processing and animal feed milling, as well as in environmental technology in polyelectrolyte dosing systems.

Features

- 3 sizes offering the following feed rates: 1.5 ~ 630 dm3/h (0.05 ~ 22 cfh)

- SINT engineering polymer body manufactured from a casting process, complete with stainless steel end plates

- Internal body geometry ensuring free material flow

- Wide range of interchangeable SINT engineering polymer or stainless steel feeder tools

- Minimum clearance between screw flight and feeder pipe

- Cavity for injection of compressed air

- High resistance to abrasion and corrosion

- Vast range of interchangeable components

Benefits

- Easy, quick cleaning due to non-stick engineering polymer surface

- Comfortable maintenance due to small number of components

- Cavity for injection of compressed air to improve self-cleaning

- Minimum clearance between screw flight and feeder pipe ensuring high accuracy feeding

- Excellent price-quality ratio

Options

- Feeders manufactured from FDA and EN-approved, food-grade SINT engineering polymer

- Vertical outlet

- Pneumatic activator: supplies air through body cavity ensuring free movement of the walls and, therefore, unimpeded material flow inside the feeder (air flow can be controlled by solenoid valve or pneumatic pulse)