Description

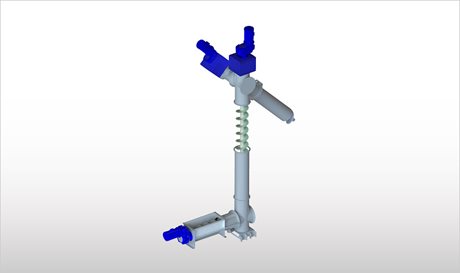

The system consists of:

– BFS Horizontal Screw Feeder

– BVS Vertical Screw Conveyor

– BIS Injector Screw

The BFS Screw Feeder receives the material from the mixer/hopper and transfers it to the BVS Vertical Screw Conveyor. The BFS Screw Feeder is a discharging equipment provided with optional inlet spouts which are pre-engineered to suit the most commonly used mixers on the market.

The BVS Vertical Screw Conveyor receives the material from the BFS Screw Feeder through a tangential or frontal discharge port. The BVS Vertical Screw Conveyor lifts the biomass to an appropriate height where it feeds it into the BIS Injector Screw.

The BIS Injector Screw collects the bulk material from the BVS Vertical Screw Conveyor and injects it into the digester below the liquid level.

Function

The TCB Bulk Biomass Conveying System is a complete and versatile screw conveyor system which extracts the bulk fraction of the biomass from the mixer/hopper, lifting and charging it into the digester of the biogas production plant.

Features

- Vertical screw conveyor with load-bearing

structure - Extra-thick heavy-duty helicoid flighting

manufactured from highly resistant steel - Standard connection for mixer/hopper

Benefits

- Clean and silent

- Versatile and efficient in conveying various organic matters

- Sturdy fabrication and mechanical components

- Small footprint

- Standardised modular industrial equipment

- Inspection and maintenance-friendly

Options

- Bridge breaker on inlet spout for mixer/hopper

- Injector screw support

- Adjustable feet for BVS in 304 SS

- 304 SS support structure for BFS